Repair and Upgrades

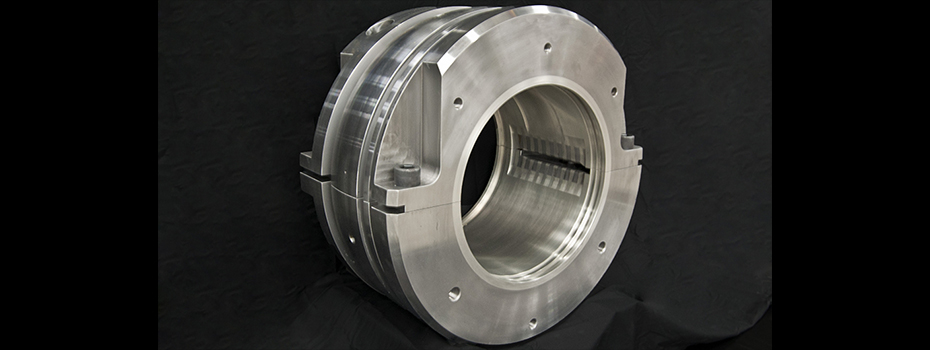

Babbitt bearing repair, from 3 inch motor bearings to 26" turbine bearings, is at the core of our expertise and business. DXP Babbitt specializes in all methods of babbitt bearing repair. By simply recasting your existing bearing and machining it to close tolerances, we can help get you back in operation quickly.

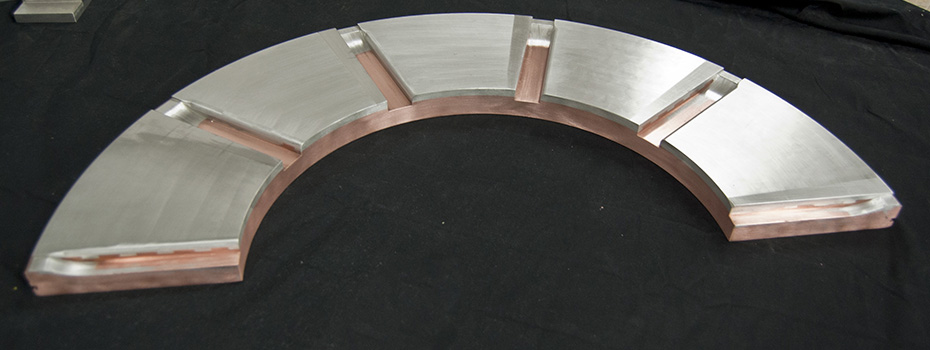

Our spin casting machine with variable frequency drive can handle up to 120" diameter and 14,000 pounds. This is the most common method of repair for sleeve bearings of all types. Also, we statically cast thrust shoes for 3" feed pumps and motors all the way up to the very largest hydro turbine units. Finally, we perform TIG repairs of tilt pad journal bearings, or use the TIG process to perform spot repairs to sleeve bearings on owner's approval. In all cases, our experienced technicians and machinists have successfully performed the repair and process many times in their careers in this specialized field.

We also specialize in small bearing repair, including 3 to 6 inch motor and fan bearings. These are often warehouse stocked items, and we can fully refurbish these bearings saving you substantially over the price of new. We use custom jigs and fixtures we have developed to maintain the OEM dimensions of these often very thin walled bearing shells, and cast babbitt to meet or exceed the OEM specifications. If the shells are severely damaged from catastrophic events, we can manufacture an entire new bearing to provide you an option to the OEM.

Our engineering staff and extensive machining capabilities can perform a number of upgrades and modifications to your trouble bearings for long term reliability and performance in your plant:

- Upgrade from lead to tin based babbitt alloys

- Full repair capability to bearing shells and housings

- Fabrication of new steel bearing shells and housings to replace cast iron

- Fabrication and complete manufacture of bearings to replace cracked or warped shells

In addition, we can also offer complete repair services for bearing shell castings, including cast iron. Many of the older hydro machines in the fleet employ very large cast iron bearing housings. Some of these have cracked, have damaged machine fits, or have previous repairs that have failed. We can offer a number of repair techniques; our engineering staff will offer recommendations based on the material and specific component. Repair methods may include brazing or metal stitching. In the event of a completely unsalvageable housing, we can recast or machine a new housing and complete the bearing to as-new condition.